- Do your chemical dosing pumps have an Interlock / flow switch with the main circulation pump?

- Is it regularly checked, tested and do you have evidence that it is functioning correctly?

These two questions are asked during the LGIS Safety Assessment. Although they are commonly answered with a confident ‘yes’, there have been several incidents where a chemical bloom has entered the water body, when the circulation has been off or inadequate flow, causing a major incident.

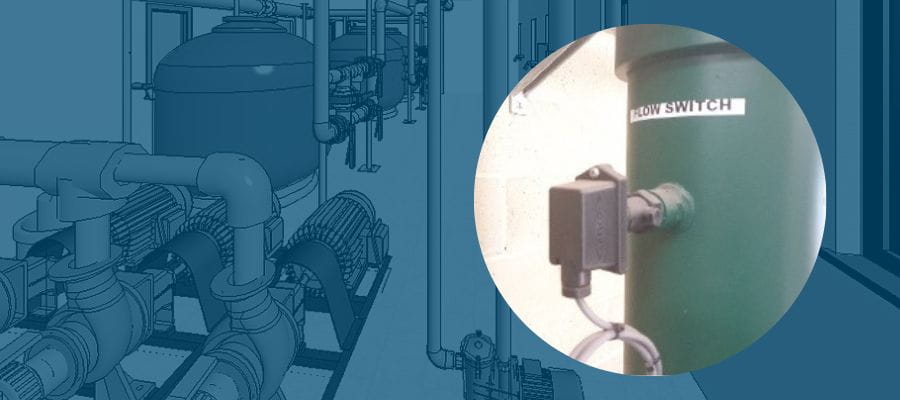

About the switch

The Interlock / Flow Switch sends a signal to the chemical dosing pumps to stop chemicals dosing if there is inadequate flow of water through the filtration system. This prevents chemical dosing and build-up in the line so when your circulation pump is back in operation it’s not dispensing an excessive amount of chemicals into your swimming pool, creating a chemical bloom.

Department of Health guidelines

According to the Code of Practice for the Design, Construction, Operation, Management and Maintenance of Aquatic Facilities – Section 3.4.2 Water Treatment – Design and Installation:

- Chemical dosing equipment shall be designed and installed to comply with the following requirements.

- Chemicals shall not feed into the water if the pumping equipment or power supply fails.

- Operation of the system shall cease if there is inadequate flow of water through the filtration system that would prevent the chemicals from being properly dispersed throughout the aquatic facility water body.

Ensuring compliance

For successful compliance during the LGIS/RLSSWA Assessment the facility will need to provide evidence that these devices are installed and working effectively. Royal Life Saving WA suggests this becomes included in your facility servicing scope and is documented in the service report from the service contractor.

More information on Royal Life Saving WA’s safety assessment services can be found here.